I-CATALYSTS

-

I-AGO-0X5L Catalyst for PA Production kusuka ku-0-xylene

Ukuma Kwekhemikhali

I-V-Tl yensimbi ye-oxide embozwe kusithwali se-inert

Izakhiwo Zomzimba

I-Catalyst Shape

Indandatho evamile engenalutho

Usayizi we-Catalyst

7.0*7.0*3.7±0.1mm

Ukuminyana kwenqwaba

1.07±0.5kg/L

Inombolo Yesendlalelo

5

Amapharamitha wokusebenza

Isivuno se-Oxidation

113-115wt% ngemuva konyaka wokuqala

112-114wt% ngemuva konyaka wesibili

110-112wt% ngemuva konyaka wesithathu

I-Hot Spot Temperature

400-440℃(Ejwayelekile)

I-Catalyst Pressure Drop

0.20-0.25 Ibha(G)

I-Catalyst Lifetime

> iminyaka emi-3

Isimo Sokusetshenziswa Kwezimboni Zokuhweba

Ukungena komoya

4. 0NCM/ishubhu/h

Umthwalo we-oxylene

320g/ithubhu/h (Okuvamile)

400g/ithubhu/h(Ubukhulu)

0-xylene ukugxila

80g/NCM (Ejwayelekile)

100g/NCM (Ubukhulu)

Izinga Lokushisa Kasawoti

350-375 ℃

(Ngokwesimo sesitshalo seklayenti)

Izici Zomkhiqizo Namasevisi I-AGO-0X5L, inani lezendlalelo ze-catalyst yizendlalelo ezingu-5, ezithuthukisiwe futhi zenziwe ngcono ngokusekelwe kubuchwepheshe obuthuthukisiwe be-phthalic be-hydride catalyst eYurophu. Lolu hlobo lwe-catalyst lunezici zomsebenzi ophezulu kanye nesivuno esiphezulu, futhi ikhwalithi yomkhiqizo izinzile futhi inokwethenjelwa. Njengamanje, ucwaningo lwe-catalyst kanye nentuthuko kanye nokukhiqizwa kwesivivinyo sekuqediwe, futhi ukukhiqizwa kwe-industria kuzokwenziwa maduze.

Nikeza ukulayisha kwe-catalyst kanye nezinsizakalo zobuchwepheshe zokuqalisa.

Umlando Womkhiqizo U-2013—————————————–R&D waqala futhi waphumelela

Ekuqaleni kuka-2023—————-R&D iqalwe kabusha, ukuqinisekiswa kuqediwe

Maphakathi no-2023———————Ukukhiqizwa kwesilingo sezimboni

Ekupheleni kuka-2023—————————Ulungele ukulethwa

-

I-AOG-MAC01 I-benzene Oxidation yombhede ongashintshi ku-Maleic Anhydride catalyst

I-AOG-MAC01I-benzene Oxidation enemibhede engaguquki ibe yi-Maleic Anhydride catalyst

Incazelo Yomkhiqizo:

I-AOG-MAC01Fixed-bed benzene Oxidation to Maleic Anhydride catalyst taking

Kusetshenziswa i-oxide ehlanganisiwe kusiphathi esingenayo, i-V2O5 ne-MoO3 njengezingxenye ezisebenzayo, isetshenziswa

Ku-fixed-bedbene oxidation ku-maleic anhydride. I-catalyst ine-

Izici zomsebenzi ophezulu, ukuqina okuphezulu, izinga lokuguqulwa kwama-98% -99%, kuhle

ukukhetha kanye nesivuno esifinyelela ku-90% -95%. I-catalyst ilashwe ngokuvula ngaphambili

kanye nokucubungula impilo ende, isikhathi sokuqala sokungeniswa sincishiswa kakhulu,

Impilo yesevisi yomkhiqizo ifika eminyakeni emibili noma ngaphezulu.

Izakhiwo zomzimba namakhemikhali:izinto

inkomba

Ukubukeka

Umbala omnyama-oluhlaza okwesibhakabhaka

Ukuminyana kwenqwaba,g/ml

0.75-0.81g/ml

Ukucaciswa komumo, mm

Indandatho evamile engenalutho 7 * 4 * 4

Indawo engaphezulu, ㎡/g

>0.1

Ukwakheka kwamakhemikhali

I-V2O5, i-MoO3 nezithasiselo

Amandla okuchoboza

I-Axial10kg/ingxenye, i-radial5kg/ingxenye

Izimo zokusebenza eziyisethenjwa:

Izinga lokushisa,℃

Isigaba sokuqala 430-460 ℃, esivamile400-430 ℃

Isivinini sesikhala,h -1

2000-2500

I-Benzene concentration

42g-48g /m³ umphumela omuhle, 52g/ /m³ ingasetshenziswa

Izinga lomsebenzi

Izinga lokuguqulwa kwe-Benzene 98%-99%

1. Ukusebenzisa i-oyili-benzene kungcono kakhulu ku-catalyst, ngoba i-thiophene nesibabule esiphelele ku-benzene kuzokwehlisa umsebenzi we-catalyst wokusebenza, ngemva kokuba idivayisi isebenza ngokujwayelekile, i-coking benzene ephezulu kakhulu ingasetshenziswa.

2. Kule nqubo, izinga lokushisa lendawo eshisayo akufanele lidlule ku-460℃.

3. Isivinini sesikhala se-catalyst phakathi kuka-2000-2500 h -1 sinomphumela omuhle kakhulu. Yebo, uma isivinini sesikhala sikhulu kunalesi, sisebenza kahle futhi, njengoba siyi-catalyst enesivinini esikhulu sesikhala.

Iphakheji nezokuthutha:

Ngesikhathi sokugcina kanye nenqubo yokuthutha, i-catalyst iwubufakazi bomswakama obuphelele, ayinamanzi futhi akufanele idlule izinyanga ezi-3 uma ibekwe emoyeni. Singakwazi ukupakisha ngokuvumelana nezimfuneko zabathengi. -

I-Gamma icushiwe i-alumina/I-Gamma Alumina Catalyst Carriers/i-gamma alumina bead

Into

Iyunithi

Umphumela

Isigaba se-Alumina

Gamma Alumina

Ukusabalalisa Usayizi Wezinhlayiyana

D50

μm

88.71

<20μm

%

0.64

<40μm

%

9.14

>150μm

%

15.82

Ukwakheka Kwamakhemikhali

I-Al2O3

%

99.0

SiO2

%

0.014

Na2O

%

0.007

Fe2O3

%

0.011

Ukusebenza ngokomzimba

BET

m²/g

196.04

Ivolumu yePore

Ml/g

0.388

I-Average Pore Usayizi

nm

7.92

Ukuminyana kwenqwaba

g/ml

0.688

I-Alumina itholwe ukuthi ikhona okungenani ifomu lesi-8, ziyi-α- Al2O3, θ-Al2O3, γ- Al2O3, δ- Al2O3, η- Al2O3, χ- Al2O3, κ- Al2O3 kanye ne-ρ- Al2O3, izakhiwo zazo ze-macroscopic ezihlukene nazo zihlukile. I-alumina ecushiwe ye-Gamma iyikristalu egcwele evaliwe eyi-cubic, engancibiliki emanzini, kodwa encibilika ku-asidi ne-alkali. I-alumina ecushiwe ye-gamma isekela i-asidi ebuthakathaka, inephuzu lokuncibilika eliphakeme elingu-2050 ℃, ijeli ye-alumina esesimweni se-hydrate ingenziwa ibe yi-oxide ene-porosity ephezulu kanye nendawo ethile ephezulu, inezigaba zoshintsho ebangeni elibanzi lokushisa. Emazingeni okushisa aphezulu, ngenxa yokuphelelwa amanzi emzimbeni kanye ne-dehydroxylation, i-Al2O3surface ibonakala ihlanganisa umoya-mpilo ongagcwele (isikhungo se-alkali) ne-aluminium (isikhungo se-asidi), esinomsebenzi we-catalytic. Ngakho-ke, i-alumina ingasetshenziswa njengesithwali, i-catalyst kanye ne-cocatalyst.I-alumina ecushiwe ye-Gamma ingaba impushana, ama-granules, imichilo noma okunye. Singenza njengemfuneko yakho.γ-Al2O3, yayibizwa ngokuthi “i-alumina ecushiwe”, iwuhlobo lwezinto eziqinile ezihlakazekayo ezinezimbobo, ngenxa yesakhiwo sayo sezimbotshana ezilungisekayo, indawo enkulu ethize, ukusebenza kahle kwe-adsorption, indawo enezinzuzo ze-asidi nokuzinza okuhle kwe-thermal, i-microporous surface enezici ezidingekayo ze-catalytic action, ngakho-ke iba yi-catalyst ye-catalyst, i-catalyst esetshenziswa kakhulu umthwali embonini yamakhemikhali namafutha, futhi idlala indima ebalulekile ku-hydrocracking kawoyela, ukucwenga i-hydrogenation, ukuguqulwa kwe-hydrogenation, ukusabela kwe-dehydrogenation kanye nenqubo yokuhlanza i-exhaust yemoto.I-Gamma-Al2O3 isetshenziswa kabanzi njengesithwali se-catalyst ngenxa yokuguquguquka kwesakhiwo sayo se-pore kanye ne-asidi engaphezulu. Uma i-γ- Al2O3 isetshenziswa njengesithwali, ngaphandle kwalokho ingaba nemiphumela yokuhlakaza nokuzinzisa izingxenye ezisebenzayo, futhi inganikeza isikhungo esisebenzayo se-asidi ye-alkali, ukusabela kwe-synergistic nezingxenye ezisebenzayo ze-catalytic. Isakhiwo sezimbotshana kanye nezindawo ezingaphezulu ze-catalyst zincike kusithwali se-γ-Al2O3, ngakho-ke inkampani yenethiwekhi yokusebenza ephezulu ingatholwa ukuze kutholakale ukusabela okuthile kwe-catalytic ngokulawula izakhiwo ze-gamma alumina carrier.I-alumina ecushiwe ye-Gamma ngokuvamile yenziwa ngelenduleli yayo i-pseudo-boehmite ngokusebenzisa i-400 ~ 600 ℃ izinga lokushisa eliphezulu lokuphelelwa amandla kwamanzi, ngakho izakhiwo ze-physicochemical ezingaphezulu zinqunywa ngokuyinhloko ngumanduleli wayo mbumbulu, kodwa kunezindlela eziningi zokwenza i-pseudo-boehmite, kanye nemithombo ehlukene ye-dismipseo3 i-Al-boehmite ye-Al-Boehmite ye-Al-Boehmite. Nokho, kulawo ama-catalyst anezidingo ezikhethekile ku-alumina carrier, ukuthembela kuphela ekulawuleni i-precursor pseudo-boehmite okunzima ukuyifinyelela, kufanele kuthathwe ukuze kulungiswe ukulungiswa nokuthunyelwa kokuhlanganisa izindlela zokuhlanganisa ukulungisa izakhiwo ze-alumina ukuze kuhlangatshezwane nezidingo ezahlukene. Lapho izinga lokushisa lingaphezu kuka-1000 ℃ elisetshenziswayo, i-alumina ivela kulandela ukuguqulwa kwesigaba: γ→δ→θ→α-Al2O3, phakathi kwayo γ、δ、θ kukhona ukupakisha okuseduze kwe-cubic, umehluko usekusakazeni kwama-ion e-aluminium ku-tetrahedral ne-octahedral, ngakho-ke lezi zinguquko zesigaba azibangeli okuningi kwesakhiwo. Ama-ion oksijini asesigabeni se-alpha ane-hexagonal close packing, izinhlayiya ze-aluminium oxide ziwukuhlangana kwethuna, indawo ethile yehle kakhulu.

Isitoreji:lGwema umswakama, gwema ukuskrola, ukujikijela kanye nokushaqeka okubukhali ngesikhathi sokuthutha, izinsiza ezingangenwa yimvula kufanele zilungiswe.l Kufanele igcinwe endaweni yokugcina impahla eyomile nengena umoya ukuze kuvinjelwe ukungcoliswa noma umswakama.Iphakheji:Uhlobo

Isikhwama sepulasitiki

Isigubhu

Isigubhu

Isaka elikhulu/isikhwama seJumbo

Ubuhlalu

25kg/55lb

25kg/55lb

150 kg/330 lb

750kg/1650lb

900kg/1980lb

1000kg/2200 lb

-

Ijeli ye-alumina enomumo oyindilinga evuliwe/ibhola le-alumina elisebenza kahle/ibhola le-alpha alumina

Ijeli ye-Alumina Emise Okuyindilinga ecushiwe

ngomjovo ku-Air dryerUkuminyana ngobuningi (g/1):690Usayizi We-Mesh: 98% 3-5mm (kubandakanya 3-4mm 64% kanye 4-5mm 34%)Izinga lokushisa lokuvuselela esilincomayo liphakathi kuka-150 no-200℃Umthamo we-Euiqlibrium womhwamuko wamanzi ungama-21%Izinga Lokuhlola

HG/T3927-2007

Into yokuhlola

Okujwayelekile /SPEC

Umphumela Wokuhlola

Uhlobo

Ubuhlalu

Ubuhlalu

I-Al2O3(%)

≥92

92.1

LOI(%)

≤8.0

7.1

Ukuminyana kwenqwaba(g/cm3)

≥0.68

0.69

BET(m2/g)

≥380

410

Ivolumu yePore(cm3/g)

≥0.40

0.41

Amandla E-Crush(N/G)

≥130

136

Amanzi adsorption(%)

≥50

53.0

Ukulahlekelwa Kwe-Atrition(%)

≤0.5

0.1

Usayizi Ofanelekile(%)

≥90

95.0

-

Ukusekelwa kwe-Alpha alumina catalyst

I-α-Al2O3 iyisisetshenziswa esinezimbotshana, esivame ukusetshenziselwa ukusekela ama-catalysts, ama-adsorbents, izinto zokuhlukanisa isigaba segesi, njll. I-α-Al2O3 iyisigaba esizinzile kunazo zonke ze-alumina futhi ngokuvamile isetshenziselwa ukusekela izingxenye ezisebenzayo ze-catalyst ngesilinganiso esiphezulu somsebenzi. Ubukhulu bembotshana yesithwali se-α-Al2O3 ye-catalyst bukhulu kakhulu kunendlela yamahhala yamangqamuzana, futhi ukusatshalaliswa kuyafana, ngakho-ke inkinga yokusabalalisa yangaphakathi ebangelwa usayizi omncane wembotshana ohlelweni lwe-catalytic reaction ingaqedwa kangcono, futhi ukusabela okujulile ohlangothini lwe-oxidation kungancishiswa enqubweni ngenjongo yokukhetha i-oxidation. Isibonelo, i-catalyst eyisiliva esetshenziselwa i-ethylene oxidation ku-ethylene oxide isebenzisa i-α-Al2O3 njengesithwali. Ivame ukusetshenziswa ekuphenduleni kwe-catalytic ngezinga lokushisa eliphezulu kanye nokulawulwa kokusabalalisa kwangaphandle.

Idatha Yomkhiqizo

Indawo ethize 4-10 m²/g Ivolumu yePore 0.02-0.05 g/cm³ Isimo I-Spherical, cylindrical, iringi e-rascated, njll I-Alpha hlanza ≥99% Na2O3 ≤0.05% SiO2 ≤0.01% Fe2O3 ≤0.01% Ukukhiqizwa kungenziwa ngokwezifiso ngokuya ngezidingo zenkomba -

I-Sulfur Recovery Catalyst AG-300

I-LS-300 iwuhlobo lwe-catalyst yokubuyisela isibabule enendawo enkulu ethize kanye nomsebenzi ophezulu weClaus. Ukudlala kwayo kusezingeni eliphezulu lamazwe ngamazwe.

-

I-TiO2 Based Sulfur Recovery Catalyst LS-901

I-LS-901 iwuhlobo olusha lwe-TiO2 esekelwe i-catalyst enezithasiselo ezikhethekile zokuthola kabusha isulfure. Ukusebenza kwayo okuphelele kanye nezinkomba zobuchwepheshe sekufinyelele ezingeni elithuthukile emhlabeni, futhi isendaweni ehamba phambili embonini yasekhaya.

-

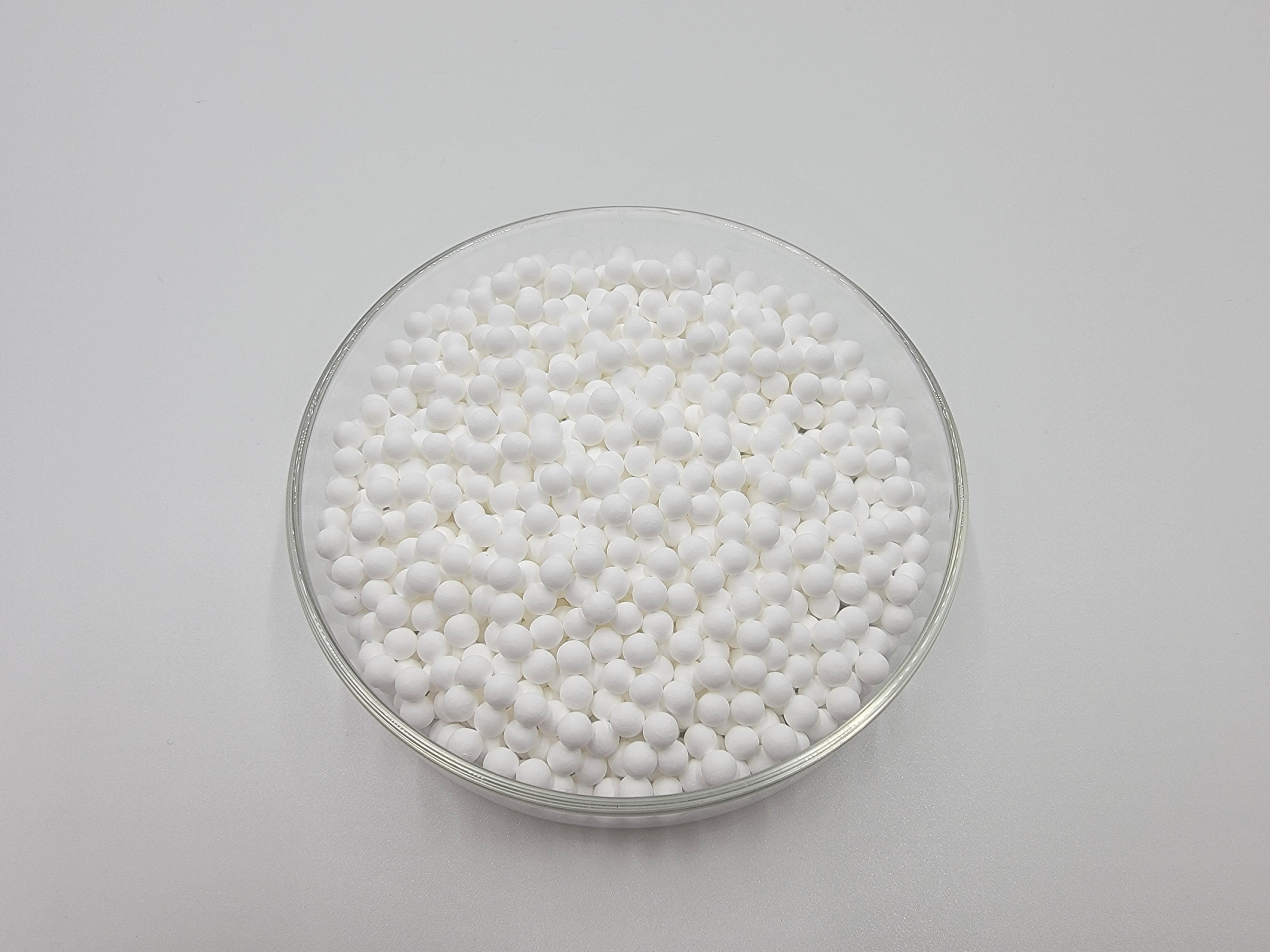

I-AG-MS Spherical Alumina Carrier

Lo mkhiqizo uyizinhlayiya zebhola elimhlophe, elingenabuthi, alinambitheki, elingancibiliki emanzini ne-ethanol. Imikhiqizo ye-AG-MS inamandla amakhulu, izinga lokugqoka eliphansi, usayizi olungisekayo, ivolumu yembotshana, indawo ethile, ukuminyana kwenqwaba nezinye izici, ingalungiswa ngokuya ngezidingo zazo zonke izinkomba, isetshenziswa kabanzi ku-adsorbent, i-hydrodesulfurization catalyst carrier, i-hydrogenation denitrification catalyst carrier, i-CO sulfur resistant carriers transformation kanye nezinye i-cataly field cataly.