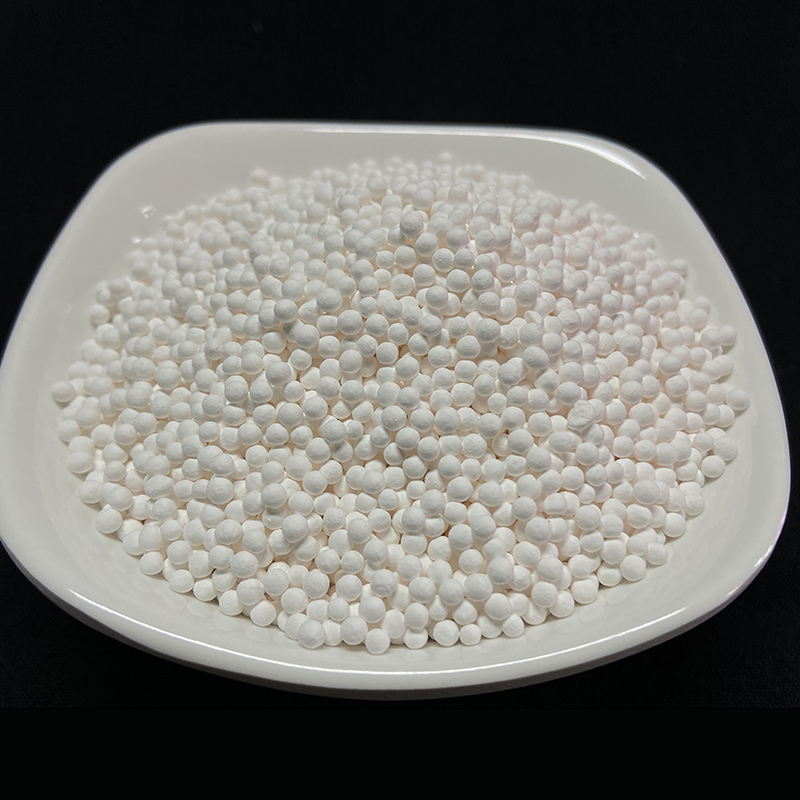

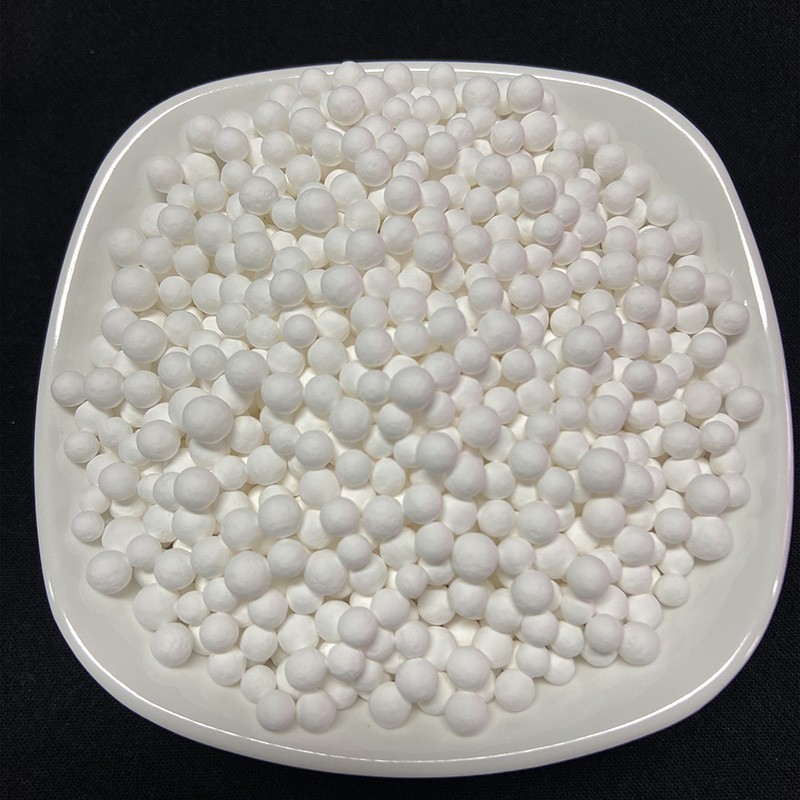

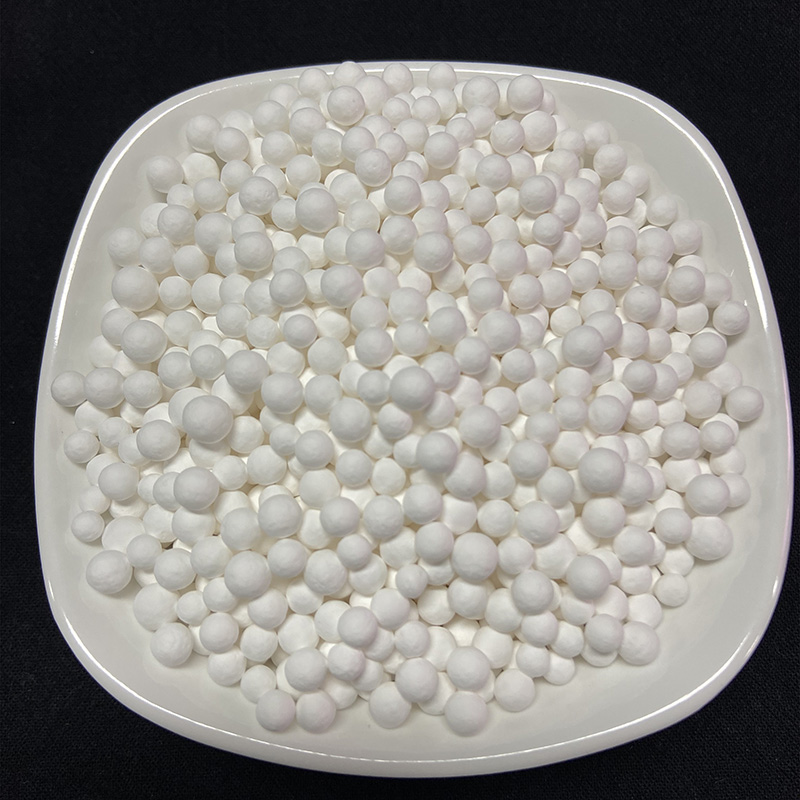

I-Alumina Ceramic Filler High Alumina Inert Ball/99% ibhola le-alumina ceramic

Izakhiwo Zomzimba Nezamakhemikhali Ze-Inert Ceramic Balls

| Izinto ezibonakalayo namakhemikhali zamabhola e-ceramic angenayo | |||||||

| Isici | Al2O3% | 60 | 70 | 80 | 90 | 95 | 99 |

| Fe2O3% | ≤0.9 | ≤0.8 | ≤0.6 | ≤0.4 | ≤0.3 | ≤0.1 | |

| Izingxenye ezisele zinganqunywa ngokuxoxisana phakathi komphakeli nomthengi lapho kudingeka. | |||||||

| ukumuncwa kwamanzi,% | 3±1,Kunganqunywa futhi ngokuxoxisana phakathi komphakeli nomthengi | ||||||

| isilinganiso, kg/m³ | 2.5-3.0 | 2.7-3.2 | 2.9-3.2 | ≥3.1 | ≥3.2 | ≥3.4 | |

| Ukuminyana ngobuningi, kg/m³ | 1400-1550 | 1400-1650 | 1500-1800 | 1700-1950 | 1800-1950 | ≥1900 | |

| Uthuli, ukuqhekeka noma ukuphuka | Isikhwama esisodwa singaphansi kuka-5% | ||||||

| Ukuchezuka kosayizi | I-Uniform sphere, isilinganiso sobubanzi obuncane kakhulu be-ceramic sphere aseqi ku-1.2 | ||||||

| Ukubekezelela Dimensional | ≤10mm | ±1.0 | |||||

| 11—25mm | ±1.5 | ||||||

| 26-50 mm | ±2.0 | ||||||

| ≥50mm | ±3.0 | ||||||

| Amandla okuwa mahhala | Izinga lokulahlekelwa ≥99% | ||||||

| Amandla acindezelayo | φ3 | ≥250 | ≥300 | ≥350 | ≥400 | ≥500 | ≥500 |

| φ6 | ≥800 | ≥1000 | ≥1000 | ≥1200 | ≥1500 | ≥1500 | |

| φ8 | ≥1500 | ≥1600 | ≥1800 | ≥2000 | ≥2500 | ≥2500 | |

| φ10 | ≥2000 | ≥2500 | ≥2800 | ≥3000 | ≥3500 | ≥3500 | |

| φ13 | ≥3000 | ≥3000 | ≥3500 | ≥4000 | ≥5000 | ≥5000 | |

| φ16 | ≥3500 | ≥4000 | ≥4500 | ≥5000 | ≥6000 | ≥7000 | |

| φ20 | ≥6000 | ≥6000 | ≥7000 | ≥8000 | ≥10000 | ≥12000 | |

| φ25 | ≥7000 | ≥7000 | ≥8000 | ≥10000 | ≥15000 | ≥17000 | |

| φ30 | ≥8000 | ≥9000 | ≥10000 | ≥12000 | ≥17000 | ≥19000 | |

| φ38 | ≥10000 | ≥12000 | ≥13000 | ≥15000 | ≥20000 | ≥22000 | |

| φ50 | ≥12000 | ≥14000 | ≥16000 | ≥18000 | ≥22000 | ≥26000 | |

| φ75 | ≥16000 | ≥18000 | ≥20000 | ≥22000 | ≥25000 | ≥30000 | |

| 50-75 | 55-75 | 60-80 | ≥80 | ≥82 | ≥85 | ||

| Izinga lokugqoka % | ≤2 | ≤1 | |||||

| ukuncibilika kwe-asidi,% | ≤6 | ||||||

| I-Alkalinity,% | ≥77 | ≥85 | ≥90 | ≥92 | ≥95 | ≥97 | |

| I-Refractoriness, ℃ | ≥400 | ≥500 | ≥700 | ≥1000 | ≥1000 | ≥1000 | |

| Imelana nomehluko wengcindezi engazelelwe | Izinga elingabhubhisi ≥ 99%, alukho ushintsho emandleni acindezelayo nengcindezi ngemuva koshintsho olusheshayo lungaphansi kwama-25% | ||||||

| Imelana nokushintsha kwezinga lokushisa okungazelelwe | Izinga elingalahleki≥99% | ||||||

| Iphakheji | Ukupakishwa kwezigubhu zensimbi | Ipakishwe ngezigubhu zensimbi, ezivalwe nge-PP ewugqinsi noma izikhwama zepulasitiki ze-PE | |||||

| Ukupakishwa kwesikhwama esilukiwe | Itholakala ezikhwameni ezilukiwe eziqinile nezimelana ne-UV | ||||||

| Qaphela: Idatha yokuminyana ngobuningi ingeyereferensi kuphela, hhayi njengesisekelo sokwamukelwa. | |||||||

Enye Inothi: Bheka Ithebula 5 Lokumuncwa Amanzi Kwamabhola Okugcwalisa angama-99

| 99 Ukugcwalisa Ukumuncwa Kwamanzi Ebhola | ||

| 99 ukugcwalisa | ububanzi | ububanzi |

| ukwakha umqulu | φ<25mm | <5% |

| Ukwakhiwa komshini wokucindezela | φ>25mm | <10% |

99.5% Izinkomba Zezobuchwepheshe

| Al2O3 | ≥99% |

| SiO2 | ≤0.14% |

| Fe2O3 | ≤0.04% |

| I-CaO +MgO | ≤0.03% |

| I-TiO2 | ≤0.06% |

| Na2O | ≤0.1% |

| K2O | ≤0.1% |

Inkomba Yomzimba Yebhola Lokugcwalisa Amakhemikhali

| ISIMO | INDEX |

| ukuthambisa umthwalo (yb/t370-1995) | Ukuguqulwa ngaphansi kwengcindezi ye-0.2mpa ingaphansi kuka-0.6% |

| Ukumelana nokushaqeka okushisayo (yb/t376.2-1995) | 1200°C phansi kuya ku-600°C. Izikhathi ezingu-10 ngaphandle kwemifantu |

| Shisa kabusha izinguquko zomugqa (gb/t3997.1-1998) | 1400 ℃ amahora angu-12, inani eliphezulu lingu-0.25%, inani elijwayelekile lingaphansi kuka-0.20% |

| Ukuminyana ngobuningi (gb/t2997-2000) | 3.2-3.50 g/cm3 |

| amandla okuchoboza | Hlangana ngaphezu kuka-230 kg/cm2 |

| I-porosity ebonakalayo | 12-18% |

| Ukuminyana ngobuningi | 2.1-2.3g/cm3 |

Chemical Packing Ball Packing

1) Ukupakisha okuvamile: isikhwama esilukiwe se-polyethylene esinesisindo esingama-25kg, kanye ne-pallet

2) Ukufakwa kwesigubhu sensimbi: Ukufakwa kwesigubhu sensimbi eyi-100L, amaphalethi anganezelwa